|

Property |

Unit |

Test Method |

Test Condition |

General Purpose PS |

| GP525N | ||||

|

Tensile Strength |

kg/cm2 (MPa) |

ASTM D-638 |

23 ℃ |

430

(40) |

|

Tensile Modulus |

kg/cm2 X104

(MPa) |

ASTM D-638 |

23 ℃ |

3.1

(3036) |

|

Tensile Elongation |

% |

ASTM D-638 |

23 ℃ |

2 |

|

Flexural Strength |

kg/cm2 (MPa) |

ASTM D-790 |

23 ℃ |

870

(86) |

|

Flexural Modulus |

kg/cm2 X104

(MPa) |

ASTM D-790 |

23 ℃ |

3.2

(3136) |

|

Izod Impact Strength |

kg-cm/cm (J/m) |

ASTM D-256 |

23 ℃

1/4″ bar |

1.7

(17) |

|

Vicat Softening Point |

℃ |

ASTM D-1525 |

Annealed 80℃×2hr 1/8” bar |

95 |

| Heat Deflection Temperature |

℃ |

ASTM D-648 |

Annealed 80℃×2hr 1/8” bar |

87 |

|

Melt Flow Index |

ASTM D-1238 |

200℃X5Kg (49N) |

6.6 |

|

|

Reidual Monomer |

ppm max. |

700 |

||

|

Specific Gravity |

ASTM D-792 |

23 ℃ |

1.04 |

|

|

Flammability |

UL-94 |

File No. E162823 |

1.5-1.7mm HB

All Color |

|

|

Characteristics |

Injection molding |

|||

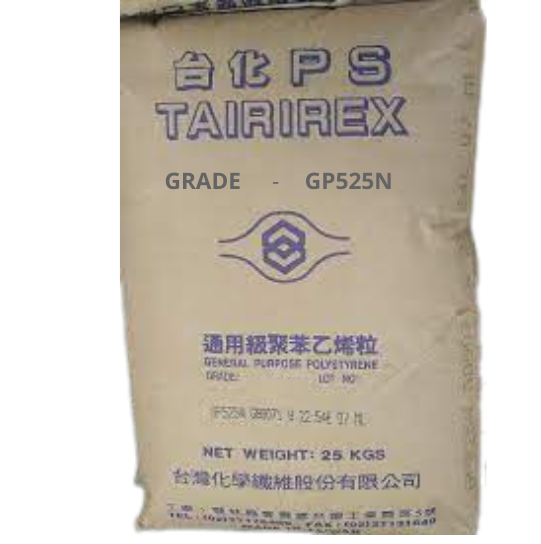

Specification: GPPS-FORMOSA-GP525N

|

There are no reviews yet.